| English | 简体中文 |

|

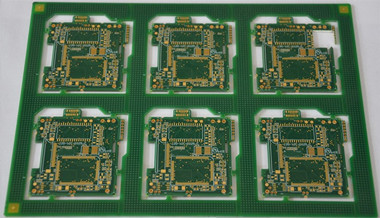

PCB fabrication, also known as PCB manufacturing, is the process of producing printed circuit boards (PCBs) that serve as the foundation for electronic devices. The fabrication process involves several steps to transform a design concept into a physical PCB. Here's an overview of the PCB fabrication process:

Design Input:

Panelization:

Substrate Preparation:

Copper Cladding:

Photoresist Application:

Exposure and Development:

Etching:

Layer Alignment and Bonding (for Multilayer PCBs):

Drilling:

Through-Hole Plating (if applicable):

Solder Mask Application:

Silkscreen Printing:

Surface Finish (if applicable):

Testing:

Final Inspection:

Packaging and Shipping:

The entire PCB fabrication process involves a combination of precision machinery, chemical processes, and quality control measures to produce reliable and functional PCBs for use in electronic products. Advanced technologies and automation play a significant role in achieving high precision and efficiency during PCB fabrication.