| English | 简体中文 |

|

BGA PCB assembly requires specialized equipment, expertise, and careful quality control measures due to the intricacies of soldering components with hidden connections. Advanced inspection methods and testing are critical to ensure the reliability of BGA assemblies in electronic devices.

- Component Placement:

Utilize automated pick-and-place machines to precisely position the BGA components onto the PCB. The solder balls on the BGA align with the corresponding pads on the PCB.

-Reflow Soldering:

The assembled PCB with BGA components goes through the reflow soldering process. The entire board is heated in a controlled manner, causing the solder paste to melt and form solder joints between the BGA and the PCB.

- Inspection:

Conduct thorough inspection, including visual inspection and automated optical inspection (AOI), to verify the quality of the solder joints. X-ray inspection is often used to examine hidden solder connections beneath the BGA.

- BGA Rework (if necessary):

If defects are identified during inspection, BGA rework may be required. This involves removing and replacing the BGA component to correct soldering issues.

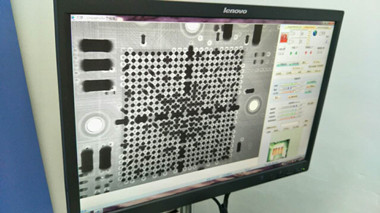

- X-ray Inspection:

X-ray inspection is crucial for examining the quality of solder joints beneath the BGA, which are not visible through traditional inspection methods.

- Functional Testing:

Conduct functional testing to ensure that the BGA components and the overall PCB assembly meet the specified electrical and functional requirements. This may include powered functional tests and other relevant testing methods.